MACHINE CONDITION MONITORING & DIAGNOSIS

Machine condition monitoring operations increasingly require the accurate monitoring of electrical signals, vibration, noise, strain and other physical signals in remote or inaccessible locations. The machine condition monitoring systems may also be subject to extreme environmental conditions. The user may be hundreds of miles away from multiple machine condition monitoring sites, yet needs to look at the data in real time, make adjustments to measurement parameters, and capture and download the complete recorded signals. The compact form factor of the CoCo-80 and CoCo-90, with their superb dynamic signal analysis capability and real-time recording, along with advances in wireless communication technology make this possible. The quick acceptance of 2.5G and 3G wireless networks have increased the cost-effectiveness of deploying remote monitoring systems worldwide.

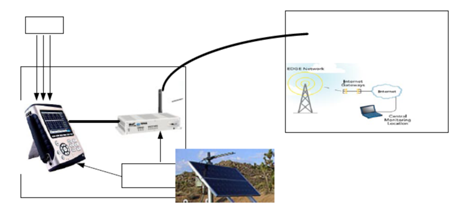

While the user can fully take the advantage of the CoCo’s graphical user interface on site, the CoCo is also a standalone network based device. When the CoCo is connected with a wireless modem, it communicates with the user through a secure internet connection. This simple integrated solution is far more cost-effective than PC-based solutions. The complete remote condition monitoring system can be described in the following diagram as an example:

Figure 1: CoCo-80 demonstrating machine condition monitoring in remote locations

Machine Condition Monitoring Application – Wind Turbine

A unique application of machine conditioning monitoring is the remote monitoring of wind turbines. The wind turbines larger than 500 KW require sophisticated machine monitoring systems.

Vibration monitoring is an important aspect in machine condition monitoring. Other quantities including electrical power quality, torque, strain and temperature are also monitored with the CoCo. Vibration analysis can detect and determine the severity of wear in the electrical generating equipment and rotating components of the turbine. This equipment consists of the main bearings, gearbox, and the generator. Vibration sensors are mounted to the bearings, gearboxes and the rotor hub and return an analog signal proportional to the instantaneous local motion. Data acquisition for machine condition monitoring requires a high sampling rate, very high dynamic range, and anti-aliasing. Wireless technology allows the CoCo to be installed in the turbine without costly cabling to ground level.

The typical sensor suite is listed below:

- Main Bearing

- 2 accelerometers (vibration)

- 1 tachometer for RPM

- Gearbox

- 1 Oil particle counter

- 4 accelerometers (vibration)

- 1 temperature sensor

- Generator

- 3 accelerometers (vibration)

- 1 temperature

Figure 2: Diagram for machine condition monitoring – wind turbine

Current practices for machine condition monitoring in the vicinity of wind turbine sites typically consist of measuring electrical signals, vibration signals with accelerometers, or tacho signals. In addition to recording and monitoring the noise and vibration, the CoCo can also be configured to generate alarms and notify engineers of excessive levels.

Recommended for Machine Condition Monitoring

Crystal Instruments recommends the following equipment for machine condition monitoring: